Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

[ad_1]

Ursa Main, the one privately funded firm within the USA that focuses solely on rocket propulsion, delivered its first copper-based 3D printed rocket engine combustion chambers out of its Superior Manufacturing lab in Youngstown, Ohio.

3D printing permits Ursa Main to hurry up engine manufacturing and apply enhancements gleaned from testing in actual time, decreasing prices. Ursa Main’s rocket engines are greater than 80 p.c 3D printed by mass and primarily constructed and examined in its Berthoud, Colorado headquarters. The copper alloy-based engine elements shall be examined for house launch and hypersonic purposes.

The manufacturing and supply cycle has now been lower down to 1 month, in comparison with the minimal six-month course of that was beforehand in place when utilizing conventional manufacturing processes.

“Velocity is of the essence in relation to producing rocket engines proper now as a result of lack of propulsion is inflicting a major bottleneck in U.S. entry to house and hypersonics testing,” mentioned Joe Laurenti, founder and CEO of Ursa Main.

In October 2021, The Ursa Main Superior Manufacturing Lab started with 3 million USD in federal monetary help from U.S. Rep Tim Ryan and Division of Protection-backed manufacturing innovation institute America Makes.

“Ursa Main’s purpose to assist set up the U.S. as a worldwide provider of rocket propulsion is according to our efforts to foster home innovation and manufacturing throughout industries in Ohio,” mentioned Rep. Tim Ryan. “I’m happy that Youngstown is residence to this state-of-the-art facility that can in the end assist the U.S. regain its management in house and hypersonic applied sciences.”

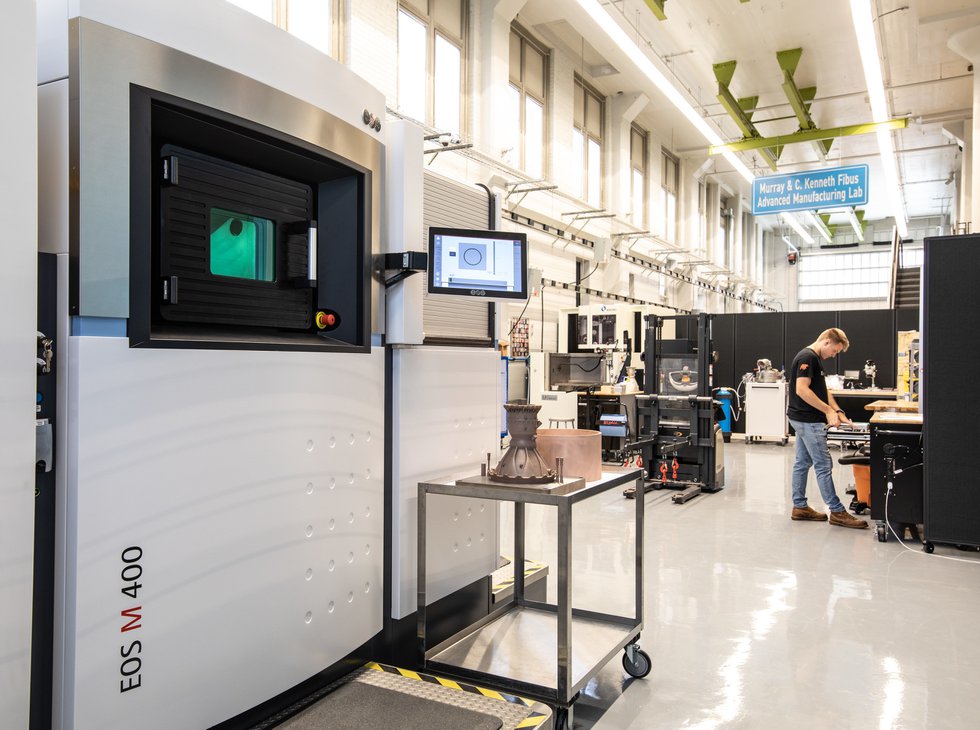

The ability is provided with an EOS large-format laser powder mattress fusion 3D printer designed to make on-demand elements for Ursa Main rocket engines. It’s positioned within the Youngstown Enterprise Incubator, an internationally recognised program centered on the event of software program and additive manufacturing corporations within the area.

John Wilczynski, Government Director of America Makes mentioned: “Succesful initiatives like this are a part of a resurgence in American manufacturing that helps strengthen our home provide chain.”

The Superior Manufacturing Lab accelerates the engine improvement course of, permitting Ursa Main to quickly iterate on design changes in-house to enhance engine efficiency and reliability. The lab was used to quickly redesign Ursa Main’s “Ripley” from a 35,000 to 50,000-pound thrust engine so as to meet market demand.

Technical classes realized from Ripley aided within the improvement and testing of the businesses two different rocket engine applications, the “Hadley,” a 5000-pound thrust, oxygen-rich staged combustion engine utilized in small launch and hypersonics, and the not too long ago introduced 200,000-pound thrust “Arroway” designed for medium and heavy launch.

Ursa Main’s versatile rocket engines can be utilized for a variety of missions, from air launch to hypersonic flight to on-orbit missions with many restarts. The corporate’s clients get to launch a few years quicker and with out the event price of constructing engines in-house.

Ursa Main has constructed and examined greater than 50 staged-combustion rocket engines so far and its engines have accrued greater than 36,000 seconds of run time, increased than the standard engine is examined previous to first flight.

Wish to talk about? Be part of the dialog on the Additive Manufacturing World Group Discord.

Get your FREE print subscription to TCT Journal.

[ad_2]