Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

[ad_1]

College of California, Berkeley (UC Berkeley) researchers have developed a freezing-modulated cross-linking strategy that might permit for the 3D bioprinting of human tissues with improved medical viability.

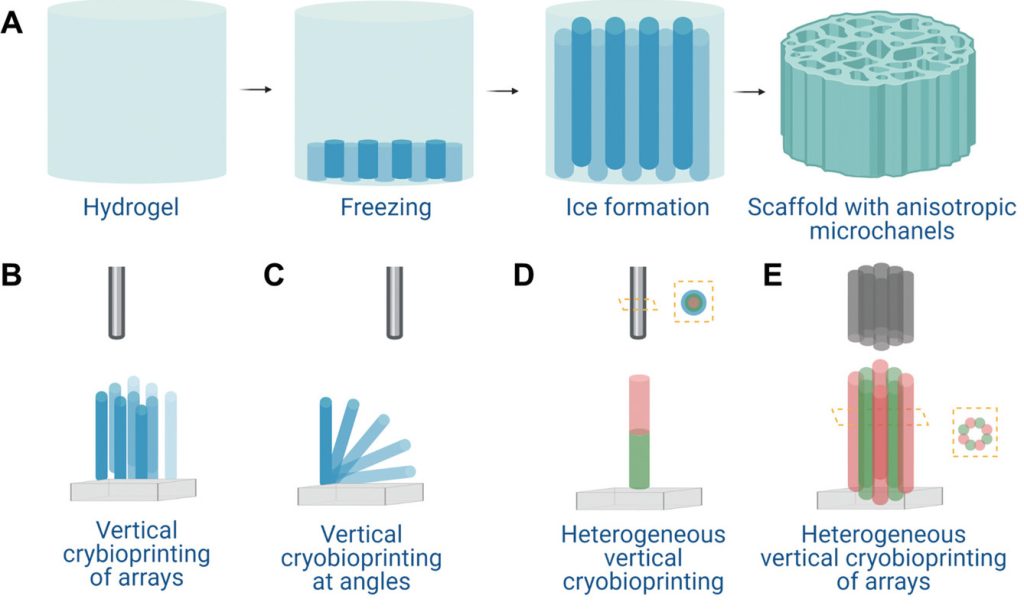

In contrast to ordinarily-bioprinted tissues, which will be too mushy to help their very own weight, the crew’s know-how sees bio-inks frozen and cross-linked, facilitating the creation of cell constructions able to retaining a desired form. Utilizing this ‘3D cryoprinting’ course of, the scientists consider it could be doable to provide sturdy alginate scaffolds seeded with cells, both for lab culturing or tissue regeneration.

Rethinking the ‘3D cryoprinting’ course of

Though 3D bioprinting has grow to be a preferred technique of participating in cell-based analysis, the know-how stays tough to make use of with softer biomaterials like sodium alginate. Regardless of the seaweed-based advanced carbohydrate’s relative affordability and powerful biocompatibility, it continues to return with prolonged lead instances attributable to crucial cross-linking.

With a purpose to get across the drawbacks of such bio-inks, many researchers now print them into constructions layer-by-layer utilizing 3D cryoprinting, a course of that sees them quickly cooled and frozen into place upon deposition. Nevertheless, because the Californian crew level out of their paper, the know-how’s strategy to solidifying supplies additionally makes them tough to cross-link, and thawing can result in their collapse.

To make issues worse, the scientists add that 3D cryoprinting typically necessitates using inside crosslinking, which solely permits bio-inks to be extruded for brief durations earlier than they undergo from excessive viscosity, and the method of defrosting additionally reduces scaffold viability, significantly in tissue engineering purposes.

Honing a freezing-modulated various

Of their efforts to provide you with a substitute for typical 3D cryoprinting, the scientists have developed freezing-modulated cross-linking, a course of through which constructions are frozen however then thawed in a calcium tub. By way of doing so at a managed charge, the crew says it’s doable to cross-link tissues layer-by-layer, thus permitting them to retain a set form.

Throughout the early levels of their know-how’s R&D, the researchers started through the use of a mathematical mannequin to establish the optimum temperature at which supplies needs to be frozen and defrosted. As soon as these parameters had been established, the crew harnessed their course of to provide a wide range of multi-layer alginate objects, which may very well be refrigerated or stored frozen for later cell-based experimentation.

Preliminary outcomes confirmed the amount of calcium that supplies have been bathed in, had no influence on their shrinkage, and reducing the method’ temperature wasn’t discovered to yield any accuracy advantages both. That stated, when it got here to defrosting the scaffolds, melting these at the next charge did trigger them to shrink, with tissues cross-linked at 20 °C turning into smaller than these cross-linked at -0.05 °C.

Having recognized cross-linking at an object temperature of -80 °C and tub temperature of -0.05 °C, as the best parameters for his or her course of, the researchers say it might now widen 3D cryoprinting’s purposes. Nevertheless, the crew additionally accepts that additional analysis is required into the best way their strategy impacts cell viability, one thing that’ll be important to its deployment in regenerative tissue R&D.

Freezing in 3D bioprinting improvement

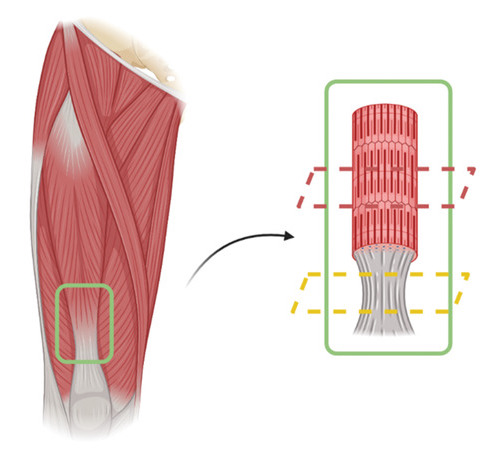

As is the case with conventional 3D bioprinting, cryoprinting continues to be the topic of intense lab-based analysis, with scientists around the globe searching for to good and experiment with the know-how. Earlier this yr, a crew at Harvard Medical College and Sichuan College developed a novel technique of 3D printing freestanding, mixed-cell tissues, together with reside human muscle-tendons.

Again in 2018, researchers at Imperial Faculty London, additionally developed the same methodology, which concerned utilizing cryogenics to 3D print mushy tissues, able to fooling the human lungs and mind into pondering they’re real. On the time, the seeding of reside dermal fibroblast cells onto 3D printed scaffolds was seen as an vital step ahead that showcased the potential of cryoprinted inks.

Elsewhere, different 3D bioprinting developments have seen the know-how superior to the purpose that it may be used to provide highly-complex cell constructions. Late final yr, as an example, scientists on the College of Montréal, Concordia College and the Federal College of Santa Catarina, have been in a position to 3D bioprint mice mind cells.

The researchers’ findings are detailed of their paper titled “Freezing-modulated-crosslinking: A crosslinking strategy for 3D cryoprinting,” which was co-authored by Linnea Warburton and Boris Rubinsky.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on Twitter or liking our web page on Fb.

For a deeper dive into additive manufacturing, now you can subscribe to our Youtube channel, that includes dialogue, debriefs, and photographs of 3D printing in-action.

Are you searching for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

Featured picture exhibits UC Berkeley’s Etcheverry Corridor facility, which homes its mechanical engineering division. Picture through UC Berkeley.

[ad_2]