Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

[ad_1]

Steel and carbon fiber 3D printer producer Markforged has introduced its growth into binder jet additive manufacturing for the primary time.

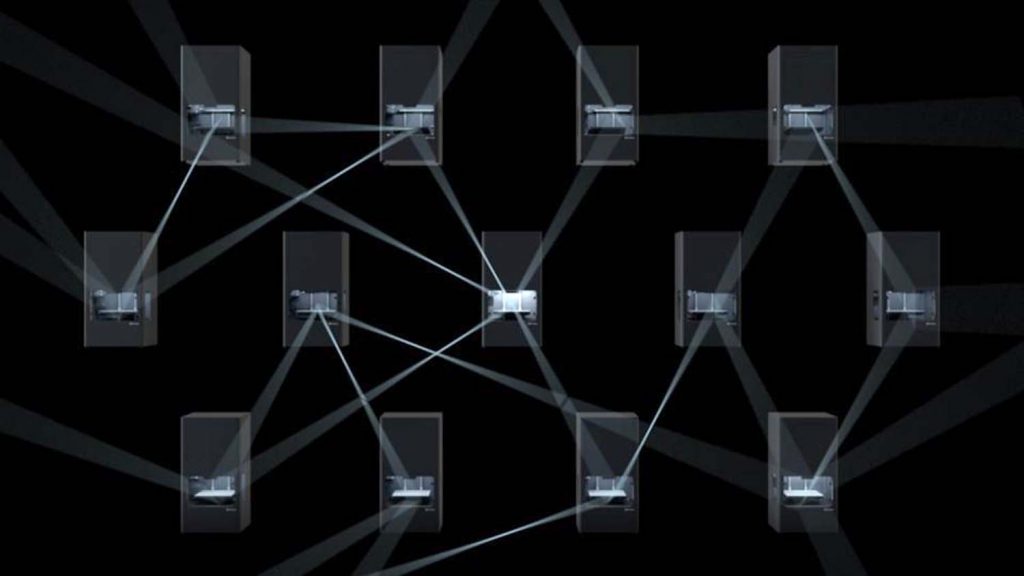

Having purchased Höganäs AB subsidiary Digital Steel, Markforged plans to combine the agency’s expertise into its Digital Forge platform. In doing so, the corporate goals to offer industrial customers with enhanced high-throughput 3D printing capabilities, and allow them to “remedy manufacturing challenges at level of want.”

“With the Digital Steel acquisition, Markforged is advancing our imaginative and prescient for distributed manufacturing by enabling the dependable, high-volume manufacturing of exact metallic elements on the level of want,” mentioned Shai Terem, President and CEO of Markforged. “Infusing Digital Steel’s resolution into the Digital Forge platform permits us to deal with new purposes within the medical, automotive, luxurious items and different industries.”

“The Digital Steel workforce has created a sturdy and scalable resolution that enhances our present applied sciences. I sit up for welcoming their gifted folks to Markforged.”

Digital Steel’s binder jet expertise

Since being based as a wholly-owned subsidiary of metallic powder developer Höganäs AB in 2003, Digital Steel has spent the most effective a part of the final twenty years establishing a portfolio of binder jet 3D printers and ancillary tools. Digital Steel’s flagship system, the DMP/PRO Collection, encompasses a printhead with 70,400 nozzles, which allow the fast jetting of two picoliter (a trillionth of a liter) droplets at a excessive stage of precision.

Because of its 160 mm-thick diabase platform, in addition to its linear motor and air bearing-driven setup, the agency says its machine can also be ready to make sure accuracy over time, whereas permitting customers to print at an “unparalleled” 8000×1600 DPI decision.

Digital Steel has regularly broadened its portfolio lately, including DM D2 device metal compatibility for its machines, earlier than introducing its personal DM Cu copper 3D printing powder in early-2021. Extra just lately, with a view to improve its methods’ capabilities, the corporate has launched an automated depowdering station, constructed to mechanize post-print powder recycling, and assist unlock serial manufacturing.

On the software program entrance, Digital Steel has additionally beforehand managed to triple the pace of the DM P2500, the opposite 3D printer in its core providing, through an improve that has since been fitted to the items as normal. Utilizing its ever-growing portfolio, the agency says its clientele are actually more and more in a position to produce high-surface high quality elements in quantity, whereas its expertise itself is “making strides” in new purposes.

Markforged’s Digital Forge growth

Agreed within the type of a ‘definitive settlement’ with Höganäs AB, Markforged’s deal to purchase Digital Steel will see it pay $32 million in money, and round 4.1 million shares in widespread inventory for full management of the agency. Markforged has additionally agreed to pay $1.5 million in money to settle sure intercompany balances, and whereas the deal stays topic to sure circumstances, it’s anticipated to undergo throughout Q3 2022.

When it comes to the motivations behind the transfer, Markforged sees binder jetting as “a extremely scalable additive manufacturing expertise,” that permits the manufacturing of elements from a spread of various metals. As such, the corporate expects that including the method to its present Digital Forge providing, will enable it to “broaden its addressable market by fixing new buyer issues” shifting forwards.

Markforged additionally believes that by utilizing its enhanced platform, producers will now be capable of create purposeful metallic elements in excessive volumes with a minimal quantity of setup. That is seen by the agency as notably vital, given the prolonged design-to-manufacturing instances usually related to conventional processes, thus its acquisition might assist make 3D printing simpler to deploy and scale on-demand.

“Markforged’s easy-to-use platform, best-in-class software program capabilities and materials experience felt like a pure match for the way forward for our expertise,” provides Christian Lönne, CEO of Digital Steel. “With Markforged’s expertise and go-to-market scale, we’re assured that we will develop our expertise collectively and assist extra producers produce the high-volume metallic elements they should drive extremely productive and cost-efficient operations.”

Assessing the binder jetting competitors

It’s debatable that binder jetting was introduced again into the highlight with Desktop Steel’s compelling strategy to advertising. The phrase round commerce reveals was usually beneficial, with binder jet enterprises welcoming the renewed consideration on this sub-section of additive manufacturing. Now, Markforged’s Digital Steel acquisition sees it enter an ever-more aggressive binder jet 3D printing market. Desktop Steel, purchased its essential rival ExOne in August 2021 for $575 million, the current entry of latest corporations into the sector has seen a recent batch of potential binder jetting rivals emerge.

Earlier this 12 months, as an illustration, Spanish 3D printer producer Triditive revealed that it had begun working with Foxconn to develop a new binder jetting system. Though Triditive has already established a portfolio of AMCELL methods, which function utilizing a mix of binder jetting and Fused Deposition Modeling (FDM), the transfer successfully marked electronics assembler Foxconn’s entry to the business.

Elsewhere, automotive producer Volkswagen has expanded its binder jetting utilization as nicely, unveiling plans to combine the expertise into its manufacturing workflow in June 2021. In doing so, with the assistance of HP and Siemens, the corporate goals to scale back prices and improve productiveness at its essential manufacturing plant in Wolfsburg, Germany.

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Business e-newsletter or comply with us on Twitter or liking our web page on Fb.

For a deeper dive into additive manufacturing, now you can subscribe to our Youtube channel, that includes dialogue, debriefs, and photographs of 3D printing in-action.

Are you in search of a job within the additive manufacturing business? Go to 3D Printing Jobs for a choice of roles within the business.

Featured picture reveals merchants trying up at a Markforged signal outdoors the NYSE. Picture through Markforged.

[ad_2]