Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

[ad_1]

![(a) FWHMs XRCs of AlN epilayer with various thicknesses grown on Gr-buffered sapphire. (b) Estimated DD of the AlN films with and without Gr buffer layer with various thicknesses. (c) DF images of epitaxial AlN/Gr/sapphire with g = [0002]. (d) HRTEM image of the AlN/Gr/sapphire interface. (e) Raman spectra of as-grown AlN/Gr/sapphire structure. (f) Relative Raman shifts of E₂ (high) of AlN with various growth thicknesses. Credit: Hongliang Chang et al. Graphene-driving strain engineering to enable strain-free epitaxy of AlN film for deep ultraviolet light-emitting diode](https://scx1.b-cdn.net/csz/news/800a/2022/graphene-driving-strai.jpg)

The direct band hole of AlN-based supplies makes them appropriate for fabricating DUV optoelectronic units, which have a variety of utility prospects within the fields of curing, water and air disinfection, drugs and biochemistry. Subsequently, reaching a high-quality epitaxy of AlN movies is of specific significance to make sure the wonderful efficiency of DUV photoelectric units.

At the moment, as a result of lack of cost-effective homogenous substrates, the optimum option to develop AlN movies is normally to carry out heteroepitaxial progress on sapphire. Sadly, the inherent mismatches between AlN and sapphire substrate inevitably introduce a wide range of crystalline defects into the AlN epilayer. Particularly, the big residual pressure within the AlN movie results in the nonuniformity of the Al distribution within the higher AlGaN layer accompanied by wafer bending, which severely limits the gadget efficiency. Subsequently, a possible technique is required to make a qualitative leap to comprehend high-quality progress of heteroepitaxial AlN movies and to fulfill the appliance necessities of DUV optoelectronic units.

Over current years, an rising technique named quasi-van der Waals (QvdW) epitaxy or distant epitaxy primarily based on two-dimensional (2D) materials has been proposed for high-quality heteroepitaxial progress of group-III nitrides. As a extensively studied 2D materials, graphene has been integrated as a buffer layer for the epitaxial progress of nitrides to successfully alleviate the lattice mismatch and thermal mismatch between the epilayer and the substrate. The earlier experiences of the epitaxial nitride movie on graphene normally said that the stress leisure of epitaxial system was realized via the weak interplay between graphene and epilayers, however there’s a lack of detailed dialogue or rigorous verification of this assertion.

Not too long ago, Dou et al. noticed the chemical bond formation on the interface between the immediately grown graphene and sapphire by aberration-corrected transmission electron microscopy and located the sturdy interplay between graphene and sapphire, which can inevitably subvert the standard notion of stress leisure through weak vdW interplay between graphene and substrate. Subsequently, the QvdW epitaxy mechanism of AlN movies on graphene deserves additional exploration, which is important to exactly manipulate the standard of AlN movies and additional elevate the efficiency of DUV optoelectronic units.

In a brand new paper printed in Gentle Science & Utility, a crew of scientists, led by Professor Tongbo Wei from Analysis and Improvement Middle for Semiconductor Lighting Expertise, Institute of Semiconductors, Chinese language Academy of Sciences, Beijing, China, and associates have efficiently achieved a high-quality strain-free AlN movie via Gr-driving strain-pre-store engineering and introduced the distinctive mechanism of strain-relaxation in QvdW epitaxy. In the meantime, the strain-free AlN movie grown on graphene/sapphire can be utilized as a dependable template layer for high-quality epitaxy of DUV-LED units.

They summarize the highlights of their research as follows:

“The dislocation density of AlN epilayer with graphene displays an anomalous sawtooth-like evolution throughout the QvdW epitaxy course of and the values are constantly decrease than that of on naked sapphire. Lastly, graphene permits the AlN movie to comprehend a 62.6% lower of dislocation density.

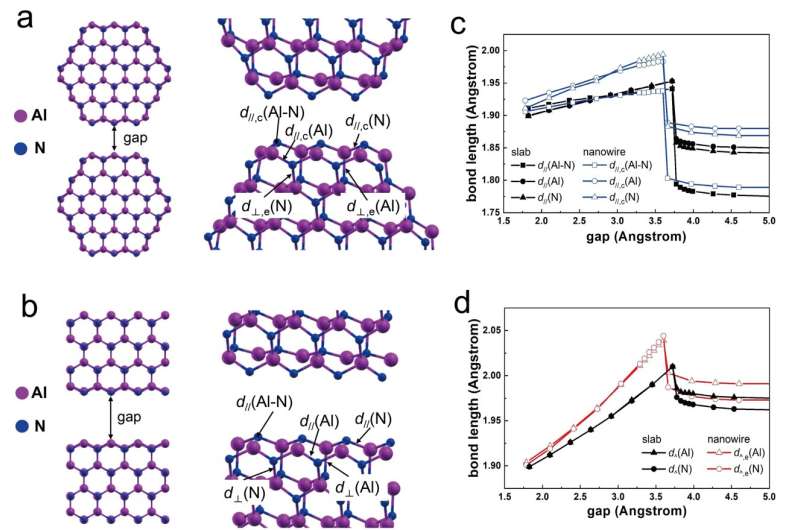

“First-principles calculation is launched to elucidate the mechanism of graphene regulating the pressure state of the AlN movie. It’s revealed that the plasma-treated graphene controls the preliminary nucleation morphology of AlN to pre-store adequate tensile pressure within the epilayer to compensate for the compressive pressure brought on by lattice and thermal mismatch throughout heteroepitaxy, thus bringing out a strain-free AlN movie.

“The reciprocal area mapping of the as-fabricated DUV-LED reveals a weak compressive pressure within the 1.8 μm n-AlGaN layer, indicating that the strain-free AlN movie as a dependable template layer permits the high-quality crystalline state of the higher LED epitaxial construction.

“The as-fabricated 283 nm DUV LED with graphene displays 2.1 occasions greater mild output energy in comparison with its counterpart on naked sapphire and favorable stability of luminous wavelength underneath a present vary from 10 mA to 80 mA, which is attributed to the higher crystal high quality with a weak residual pressure of the epitaxial construction primarily based on graphene.

“This work reveals the inner mechanism of QvdW progress of nitride to enhance the epitaxial high quality on large-mismatched substrates and undoubtedly sheds mild on the additional promotion of nitride-based gadget manufacturing.”

Supplied by

Changchun Institute of Optics

Quotation:

Graphene-driving pressure engineering to allow strain-free epitaxy of AlN movie for deep ultraviolet light-emitting diode (2022, April 8)

retrieved 8 April 2022

from https://phys.org/information/2022-04-graphene-driving-strain-enable-strain-free-epitaxy.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.

[ad_2]